After a year of running #lowdesign #lowhightech #lofab *style prototyping workshops out of the Impact Hub Accra, and building on a year plus of geeking out at the former Hub Accra, AMP can now share a cool new partnership starting this month to build a demo makerspace with Impact Hub Accra and Siemens Stiftung. (*Grassroots maker tech trend, e.g. Afri_Design_X: Ashesi Sessions)

Building an innovation engine

Hundreds of thousands of young people enter Ghana’s job market each year—ill-prepared to create their own—while hundreds of thousands of artisans and crafts(wo)men—from welders to carvers, carpenters, masons, electricians and electronics repairers, tailors, seamstresses, weavers, cobblers and sign painters to tinsmiths,copper-smiths , blacksmiths and ironmongers—are already active country-wide. If we can leverage this massive belt of grassroots (micro-)manufacturing know-how, how might we retool the emerging conversation around African ‘makers’ to better design products and environments together?

Most people who want to make things, don’t know how; others don’t know how to scale what they make. The challenge is finding what you need—knowledge, expertise, blueprints, materials, tools—to make what you want, the best way you can.

Our story starts at Agbogbloshie—an informal sector scrapyard, market, slum and park in Accra, Ghana (actually located in the Old Fadama neighborhood) that is mischaracterized by media globally as the “world’s largest e-waste dump” (compare to Adam Minter’s saner piece on Smithsonian.com). In response, 1500+ youth from Ghana, Africa, Europe and the US—750+ scrap dealers and 750+ students and recent graduates across a spectrum of STEAM fields (Science, Technology, Engineering, Arts and Mathematics)—have participated since 2014 to co-design the Agbogbloshie Makerspace Platform (AMP): a participatory design project in interclass innovation—bringing youth from different backgrounds, cultures and countries to network Agbogbloshie’s nodes and modes of making with new tools and technologies of digital design and fabrication.

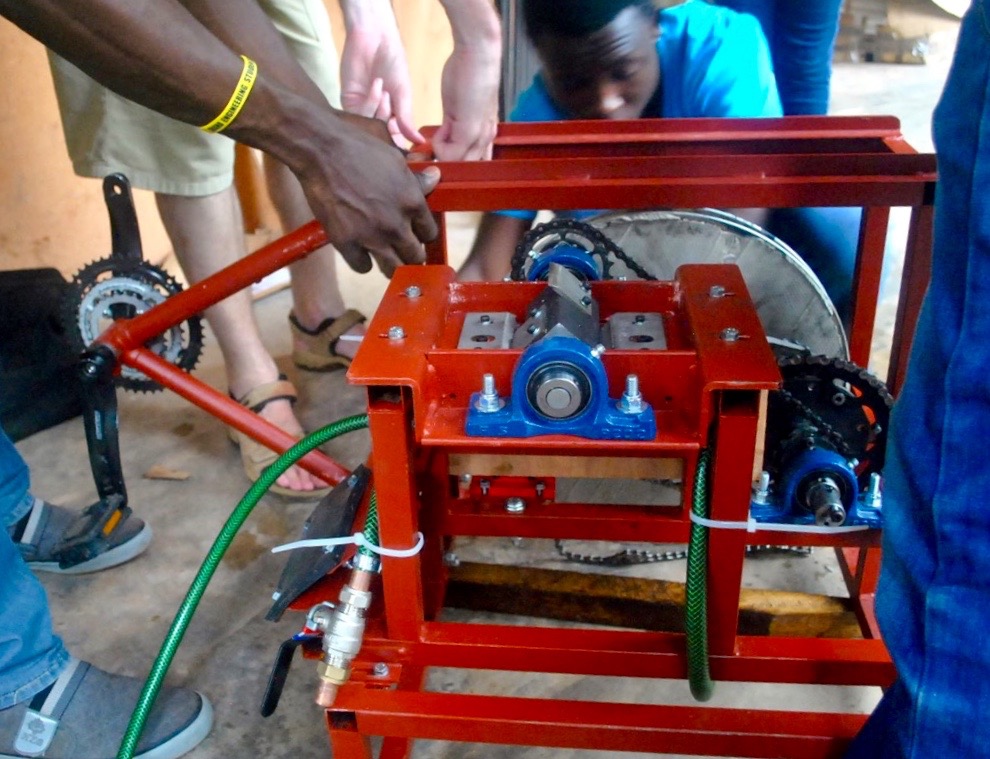

We developed a first prototype of a mobile plug-in makerspace (we call it a spacecraft) and mobile app: a trading platform for makers—to share what you need, what you have and what you make—that powers a community of plug-in spacecraft. Today we are gearing up to launch spacecraft at Agbogbloshie and at Impact Hub Accra, together with the digital network (AMP app) that links recycling with digital fabrication and distributed manufacturing. In tandem, this hybrid digital-physical platform approach operates to amplify makers’ potential—to make more, better—by making together.

|

What is a Makerspace? |

Makerspace@Impact Hub Accra

Today we are excited to announce the next phase of partnership between AMP and the Impact Hub Accra, Ghana’s pioneering co-working space and incubator for active early stage entrepreneurs: we are installing a pilot makerspace for digital design and fabrication at the Impact Hub Accra.

Initiated in 2005 with a single location, Impact Hub is the world’s leading network of entrepreneurial communities and collaborative spaces committed to generating positive impact. From Amsterdam to Accra, Singapore to São Paulo, Impact Hub supports the work of more than 12,000 members each year. The global Impact Hub community founds over 1,250 startups annually, creates more than 4,600 new full-time jobs, and serves over 2.2 million customers and beneficiaries in more than 50 countries around the world.

Impact Hub Accra, part of the first cohort of eight Impact Hubs in Africa, has a growing membership of over 100 and a broader community of nearly 7,000. Since 2015 Impact Hub Accra has hosted Africa’s biggest hackathon, “Hack for Big Choices” (supported by Facebook and WordPress), startup pitch events (most recently with The Case Foundation, for a $25,000 prize), an accelerator for top social entrepreneurs in Ghana (taking the Unreasonable Institute’s “Unreasonable Labs” global), and developed Ghana’s first digital design and innovation lab (in partnership with the US government’s Broadcasting Board of Governors).

Building a makerspace at Impact Hub Accra will integrate existing maker and entrepreneur communities to create products that solve local problems, engage real markets and have potential to scale their impact on people’s lives. Here is what we are adding to make that happen:

|

|

Equipment & Space

|

Programing & Activities

|

Scaling the impact

Over the past year, AMP and the Impact Hub Accra have in partnership run dozens of maker events on-site with 200+ participants, including: a hybrid participatory design plus lean startup-style “Makers and Development” approach to the AMP mobile app for Android; concept prototyping workshop with winners of Innovate Ghana’s Design Challenge on themes of waste and sanitation; and an interdisciplinary collaboration between students via Ashesi University’s Design Lab, design entrepreneurs in the Impact Hub Accra community, informal sector scrap dealers from Agbogbloshie, engineering students from the University of Ghana-Legon, students from l’École Spéciale d’Architecture in Paris and Princeton University’s PACE Center for Civic Engagement.

Now, starting in October 2016, we are launching the pilot Makerspace @Impact Hub Accra over a period of ten (10) months, with both the goal of upgrading our facilities and target of training 100 new makers, supporting development of 10 new product concepts to prototype stage, and incubating 2-4 ventures for a six-month period post. Our target budget for this pilot project is 120,000 USD for the makerspace equipment and build-out, running costs and a series of maker workshops, training sessions, Design Challenge and follow-up incubation.

Deeply grateful to Siemens Stiftung for offering support and collaboration toward not only the project budget to launch Makerspace @Impact Hub Accra, but also feasibility studies and seed funding for three (3) other Impact Hubs in Africa to roll-out makerspaces in their own local innovation ecosystems and grow the network.

We are scaling fast and always looking for partners, mentors, supporters, leads on sourcing used equipment and donors to help with match funding.

*This is NOT a commitment to donate money, and Thunderclap will NOT “spam” your friends on Facebook/Twitter. Thunderclap is a cool online tool that lets a group of people all share a one-time message with their friends on social media, on a particular date. The goal is to alert as many people as possible to your message—all at once.

Clicking on the “SUPPORT” button just means that you will help share us this story on 26 September, 2016. It’s like a RT on Twitter or a “share” on Facebook…in advance. Can you spare 30 seconds to help change the lives of Ghana makers?

Download from a selection of 3E-Manuals (Electrical & Electronic Equipment) here below. You can also do a keyword search using the search bar or browse the cloud of tags. Enjoy making and let us know any edits to amplify this initial work. We look forward to hear from you: info@qamp.net!

(A long-term goal of the AMP digital platform ~qampnet~ is to digitize material reality and better position automation to assist with ambiance creation. A first step is to help make people aware of what is inside their devices and equipment.)

Air Conditioner [Front & Back]

qamp.net/tag/ac/

Search @qampnet: air conditioner

Computer Desktop [Front & Back]

qamp.net/tag/computer/

Search @qampnet: computer

Microwave oven [Front & Back]

qamp.net/tag/microwave/

Search @qampnet: microwave oven

Mobile Phone [Front & Back]

qamp.net/tag/mobile-phone/

Search @qampnet: mobile phone

Plastics [Front & Back]

qamp.net/tag/plastics/

Search @qampnet: plastic

Refrigerator [Front & Back]

qamp.net/tag/fridge/

Search @qampnet: fridge or refrigerator

Monitor CRT [Front & Back]

qamp.net/tag/monitor/

Search @qampnet: tv

Washing Machine [Front & Back]

qamp.net/tag/washing-machine/

Search @qampnet: washing machine

More on spacecrafting:

In January 2016 AMP ran a one-week #ampqamp with students from Princeton University’s PACE Center for Civic Engagement focused on making short health & safety videos for the Agbogbloshie scrap dealers community, narrated in Dagbani.

This group of students, led by Ellie Sell ’17 and Christie Jiang ’17, opted not only to volunteer collaborating on the AMP project as a form of ‘alternative spring break’, but also to spend months prior planning their trip and conducting research around issues of health and safety related to unregulated e-waste processing plus weeks after their visit to Ghana editing and producing the videos. (They blogged about it here.)

Watch the Youtube playlist of videos they produced below. For more on how this connects to the full AMP project, check out this Q&A with the Princeton PACE Center. A huge thank you to the whole team from all of AMP!

Mild steel angle bar is liable to twist or bend before the truss is triangulated; to ensure that each octet truss you make is straight (±1 mm) use a straight and square metal jig with wood board forming welding bed (will burn over time, flip over before replacing). Use clamps to secure 2d truss frame to jig, and push metal against wood plate of jig with a nonconductive pipe or wood stick.

Welding: Tack weld first throughout to assemble octet truss, then complete full weld once all metal elements are held in contact. Usually a small amount of grinding required to clear sharp edges. Apply hardener coat to seal and spray 3-6 coats of automotive paint. Paint damage possible (e.g. scratches) during transport and assembly; paint touch-up work may be done after assembly.

Use a template for drilling holes in octet truss, to ensure that all holes are the same and identically located. Print on paper first,then trace or laminate onto cardboard and punch hole centers per template guides. Provided octet truss welding work is standard, dimensional tolerance of ±1 mm is achievable. Square face bolted connection is 20×20 cm, with holes of sufficient tolerance for no. 17 bolts. Drill templates are here in PDF: octet truss face joint, octet truss face joint -alt (print to A4 size sheet).

Fabrication of a semi-octet truss using 1 or 1-1/2 inch mild steel angle bar requires use of several jigs: 2d truss jig, square pyramid jig, and spacers for setting flat bar and holding string line to gauge top angle bar when welding. Each truss comprises 16 square pyramids of 4 pcs 10 or 12 mm by 16.85 cm iron rods welded to a linear array of 19.6 cm flat bar straps set in a 1 or 1-1/2 inch ms angle bar frame 20 cm wide by 282.5 cm long.

Welding: Tack weld first throughout to assemble octet truss, then complete full weld once all metal elements are held in contact. Usually a small amount of grinding required to clear sharp edges. Apply hardener coat to seal and spray 3-6 coats of automotive paint. Paint damage possible (e.g. scratches) during transport and assembly; paint touch-up work may be done after assembly.

To assembly a semi-octet truss, you will need: 2d truss jig and square pyramid jig.