Princeton PACE students in Agbogbloshie

In January 2016 AMP ran a one-week #ampqamp with students from Princeton University’s PACE Center for Civic Engagement focused on making short health & safety videos for the Agbogbloshie scrap dealers community, narrated in Dagbani.

This group of students, led by Ellie Sell ’17 and Christie Jiang ’17, opted not only to volunteer collaborating on the AMP project as a form of ‘alternative spring break’, but also to spend months prior planning their trip and conducting research around issues of health and safety related to unregulated e-waste processing plus weeks after their visit to Ghana editing and producing the videos. (They blogged about it here.)

Watch the Youtube playlist of videos they produced below. For more on how this connects to the full AMP project, check out this Q&A with the Princeton PACE Center. A huge thank you to the whole team from all of AMP!

Spacecraft . square pyramid jig

Spacecraft . 2d truss jig

Mild steel angle bar is liable to twist or bend before the truss is triangulated; to ensure that each octet truss you make is straight (±1 mm) use a straight and square metal jig with wood board forming welding bed (will burn over time, flip over before replacing). Use clamps to secure 2d truss frame to jig, and push metal against wood plate of jig with a nonconductive pipe or wood stick.

Welding: Tack weld first throughout to assemble octet truss, then complete full weld once all metal elements are held in contact. Usually a small amount of grinding required to clear sharp edges. Apply hardener coat to seal and spray 3-6 coats of automotive paint. Paint damage possible (e.g. scratches) during transport and assembly; paint touch-up work may be done after assembly.

Spacecraft . locker box

Spacecraft . octet truss fabrication process

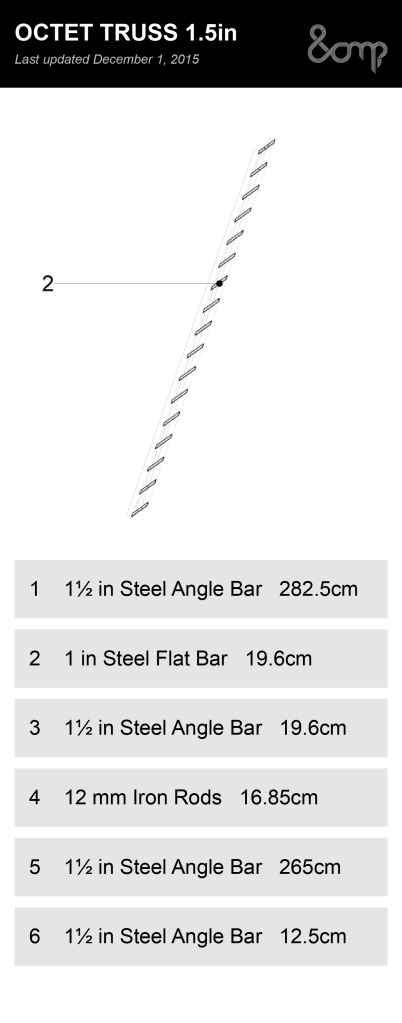

Fabrication of a semi-octet truss using 1 or 1-1/2 inch mild steel angle bar requires use of several jigs: 2d truss jig, square pyramid jig, and spacers for setting flat bar and holding string line to gauge top angle bar when welding. Each truss comprises 16 square pyramids of 4 pcs 10 or 12 mm by 16.85 cm iron rods welded to a linear array of 19.6 cm flat bar straps set in a 1 or 1-1/2 inch ms angle bar frame 20 cm wide by 282.5 cm long.

Welding: Tack weld first throughout to assemble octet truss, then complete full weld once all metal elements are held in contact. Usually a small amount of grinding required to clear sharp edges. Apply hardener coat to seal and spray 3-6 coats of automotive paint. Paint damage possible (e.g. scratches) during transport and assembly; paint touch-up work may be done after assembly.

To assembly a semi-octet truss, you will need: 2d truss jig and square pyramid jig.

The Sounds of Agbogbloshie

We have a huge blog posts backlog, but here is at least one regarding sound recording conducted in Agbogbloshie on the 22/7/2014 (a while back!), the day Ellen Foster, PhD candidate at Rensselaer Polytechnic Institute, Troy, NY visited AMP (Thank you for recording a major part of it). So much has been said about Agbogbloshie but not often the right story! Agbogbloshie is a busy recycling/making center and you can hear the rhythm of the hammers, dismantling or making…

‘Sounds of Agbogbloshie‘ playlist on Soundcloud:

Spacecraft . bifold hangar doors

M&D Super Concerned Citizens Special Investigators Series

This past fall 2014 semester at ESA, students were assigned to become “Super Concerned Citizens Special Investigators (SCCSI)” and make a movie summarizing their findings about e-waste. I am very proud of my students and I thank them for their dedication this semester! I am not uploading the videos because some have used copyrighted sound material… Anyway… Below are their stories:

COLOMB, Gilles + MARION-ARDALAN, Cyrus + TOSTIVINT, Théo

Pros & Cons

15’58

We tried to investigate how to repair a computer that could be considered as reaching its term of life. After looking quickly into the solutions given to us by asking to a certain number of shops (big corporations and small repair shops) we decided to record ourselves into a journey of finding a solution to this problem. The main thoughts that guided us was; is this piece of electronic built to break down and will it be possible to repair it in order to keep it as long as possible? We began our investigation thinking that all the different shops had the same answer to our problem: by replacing our old device by a new one. After dismantling our device and comparing it to newer product we arrived to the conclusion that trying to perfect a product in its weight or thickness, can, with the time, make it more and more difficult to repair especially by making custom made parts or replacing a simple screw by a weld attachment. We can relate this issue to the new ways of designing objects and architectures today; are we building to last or to replace? Is there a programmed obsolescence in architecture? Can we replace a “Gehry” part as well as a “Prouvé” part?

SEBBAN, Julien

More 2 Recycle

5’57

Love2recycle is a website which proposes a solution to collect electronic waste and sell it through the platform. The company buys the old phones for a cheaper price, repairs it and sells it back to other parts of the world. But, how can I make sure that my phone ends up in good hands when I use online recycling platforms? I decided to make my own research and I called the company. By investigating the system, I found a lack of transparency: phones are going sooner to the trash and it increases the quantity of e-waste.

Who is to blame? Who is responsible? Who cares?

The solutions are terrific in the short term. But wouldn’t it be a little more green if companies encouraged consumers to change consumption habits altogether?

The city has evolved… and we are becoming more and more dependent on the machine. Phones have become the extension of our bodies. People are left aside. Design and technology are excluding the person who doesn’t have access to new products. There is a digital divide which creates a huge discrepancy. The society is designed to exclude you when you don’t have a phone.

How can you pay? How can you call?

GHABRA, Hania

Give Way to Giving

7’57

From the moment of purchase of an electronic to the day it is no longer functional, what can we do as responsible consumers to deal with our e-waste. I have looked into my options, and although repairing the object is probably the most popular option to follow, I decided to represent the part of the population with limited technical ability: The non-repairmen and women. Why throw away in the trash when you could give it to someone to make good use of it? The real question is, however, how to find people in need of your e-waste and be sure they are not just another person planning on selling the e-waste for profit? After finding a website that links people willing to give away their object to others willing to take it for their own use, I decided to do a trial and give away my own e-waste. There was instant demand for my iPod, and I was overwhelmed by the number of requests I received. Of course that raised another question: Who are these people requesting my e-waste and which one of them is truly in need of it? With all these unanswered questions, came an interesting twist of events: I realized that my iPod was not broken… it just needed to be charged. Suddenly, I was no longer willing to give away my electronic… This change of heart illustrates the sort of relationship we have with our electronics. We feel possessive of our electronics in their functional state. However, they lose their value once they are broken or out of style. It becomes so easy for us to abandon what we once cherished.

BALAS, Léonard + WOLF-HANSEL, Ginosar

Where Does the E-waste go?

4’23

During our short investigation, we tried to answer a question that bothered us as citizens living in a big city: where does all our e-waste go?

When we started to follow our piece of e-waste from the street, we expected to find an answer to this question. But it immediately became clear that it was not going to be easy. After the many bureaucratic obstacles we encountered, we decided to examine whether and what other citizens of Paris think about the daily waste they throw to the street.

Almost everyone answered the same way. The place where the e-waste travels to is UNKNOWN. Surprisingly, even people who worked for the municipal system did not know about the destination of the waste after they leave it in the street. The most surprising fact we discovered was that nobody seems to care about it…

Life in modern cities enables us to ignore some of its constituent systems, if we prefer not to do so. Impressive facades hide poor neighborhoods, underground systems maintain sewage. Thus, life seems to be easier, compared to the past. Nevertheless, it should not be an excuse for responsibility diffusion. We created this animated movie in order to raise the awareness of people to their property, their e-waste.

By a simple web search it is possible to learn about the terrible pollution in African countries caused by toxic e-waste. The information is very accessible but only few people are interested in that and look for it.

How can we, as responsible citizens, take responsibility and change this undesired situation?

There are many answers to this question. what we want to focus on in the future is how to use design as a tool in order to raise awareness and transparency about the life circle of the product we are using, and not only to know where it goes after its broken, but also how it is working.

As architects and designers, how can we integrate in our design the transparency, and design a product who could tell a story?

When the first computers were invented, people saw them as magic boxes. Today, it seem like it never changes. Our whole life going around our smartphones, televisions and other electronic/electric products, but because everything is hidden behind plastic and glass, we can never understand how this product really works, and people don’t really care about what is inside their machines. Maybe we lost something on the way… maybe it’s the curiosity, or the desire of knowledge. If the product works we use it, if it breaks… we buy a new one.

If we would understand more how our electric product is working, maybe we would care more where they go after they break. Making it invisible to understand and easy to fix can decrease the amount of e-waste in the streets and in poor countries.

HIGA, Akemi

A Laptop Journey in Lima, Peru

6’32

This movie shows the process of recycling an e-waste, in this case a laptop, in the city of Lima-Peru. Because the process took place earlier this year, the story is shown as a kind of chronicle of what happened and the things I learned about the infrastructure and system for recycling available now in Lima. This story takes you with me throughout what I learned in that moment and what I am learning right now about the limits and opportunities for e-waste inside the informal and formal systems simultaneously managed in my everyday live. Starting from getting the laptop, the life spam that it got, the process of recycling it, and the realization that not everything is as simple as one first imagined. The process doesn’t always end where we want it to; and it is up to us to finds alternative ways to deal with the challenges. That is what makes us Super Concerned Citizens Special Investigators.

Architecture here plays the role in two ways: in the overall design of better infrastructure for not only separating and classifying but for actual recycling of technological goods; and as a designer in the questioning of how much of a laptop can be turned into other goods. How can we recycle something that is not designed to be recycled? And even if it is meant to be recycled, how can we accomplished that if the infrastructure doesn’t exist? Who is to blame? The starting point of the process or the last?

KIM, Joongi + KIM, Yongyeob + KWON, Seulkee

Finding the Way to Recycle E-Waste

7’54

How can we decrease e-waste?

When a smart phone part breaks, we usually buy a new phone… and this even if only one component breaks.

Could we make a new product using the working parts of a smart phone? Can this practice of making new items out of working parts of a broken phone decrease the production of e-waste?

We asked an expert about making items out of parts of phone parts.

ABREO, Daniel

Design for (Dis)assembly

4’02

Buy it, use it, break it, fix it, trash it, change it, mail – upgrade it,

Plug it, play it, burn it, rip it,

Cross it, crack it, switch – update it…

In the past few years headphones market have known a fantastic growth with the multiplication of portable players like mp3 players, iPhones, tablets among others. They have since then become a fashion accessory and as a result many brands release new models every season leading people to consumerism and to change their headphones every other month. In many cases they extremely fragile and have a very short lifespan; yet, the truth is that most of the broken headphones work perfectly and you just need to solder the wires together again. But instead the entire product is just thrown away. Is it an intended weakness?

In this video I tried to show how the (Dis) Assembly process of an object can dictate the evolution of this waste chain. I also try to raise awareness of the consequence or our acts and current education. Most of the waste produced in the world is produced by the construction industry. Architects and designers should acquire a basic notion of the way their products work. They should learn not to systematically rely on others. They should enrich their culture and reaffirm their knowledge in their field. Architects and designers should learn to properly analyze a situation to better re-use or repair instead of always starting from scratch.

VILLALBA, Joaquin

iFix my iPhone

6’32

As part of a research on e-waste, I decided to investigate what are the possibilities existing with a broken device, in my case, an old iPhone that wasn’t being use because it was damaged. Time is an inevitable degrading factor that must be managed in order to guarantee the longest lifetime of objects. Getting rid of old devices is not a solution, because that it is moving the e-waste from one place to another, and because this devices are actually still useful; therefore my final goal was to keep the phone in a usable condition. The idea is that everything is going to get damaged and old with time, and the solution is not to be afraid and get rid of the products or get new ones, but to foresee and maintain. Time is the agent that can make an antique of an old car, but it can also cause structure to rust. The solution is to reach for the tools we need, and that are not given to us, to apprehend the influence of time. We are powerful among creations and not the other way.

Plastic Micro-factories in Agbogbloshie

Plastic waste in Ghana has become a major social and ecological problem, due to the adverse effects of plastic pollution on both human health and the environment. Especially during periods of flooding, plastic waste chokes the drainage systems of most Ghanaian cities. The need for initiatives to improve sanitation in our community is of great importance. Of the many local waste management companies, only few practice segregation and recycling of waste — and not yet at scale. In the area of plastics recycling, Blowplast recycling is one of the formal organizations which recycles water sachet and black bags in large volumes. What a lot of people do not realize is that plastics recycling in Agbogbloshie is a major activity within the informal sector recycling industry.

Because we are current developing a plastics micro-factory as part of the AMP toolset (one of first prototypes is a mini-kiln for moulding plastic tiles), we continue to work with Agbogbloshie plastics recyclers in order to better understand how the process works now and how it can be improved.

One of the more advanced industrial setups we have come across is located on Abosey Okai Road. Stages in the process flow include sorting, shredding and pelletizing. This micro-factory engages more then 20 youths in Agbogbloshie in full-time employment! The sorted plastics are ground using a milling machine (see picture below) which is connected to a water bath. Shredded plastics are then collected and dried. Finally, the shredded high-density polyethylene (HDPE) are pelletized using an extrusion machine. These pellets — made out of plastic waste from all over Accra — are then sold as feedstock to formal industries both in Ghana and globally that have the capability to produce plastics films.

The existing model of plastics micro-factories in Agbogbloshie deserves support and attention. In effect they perform a massive public service: cleaning up the city of Accra, by making profits from our plastic waste.