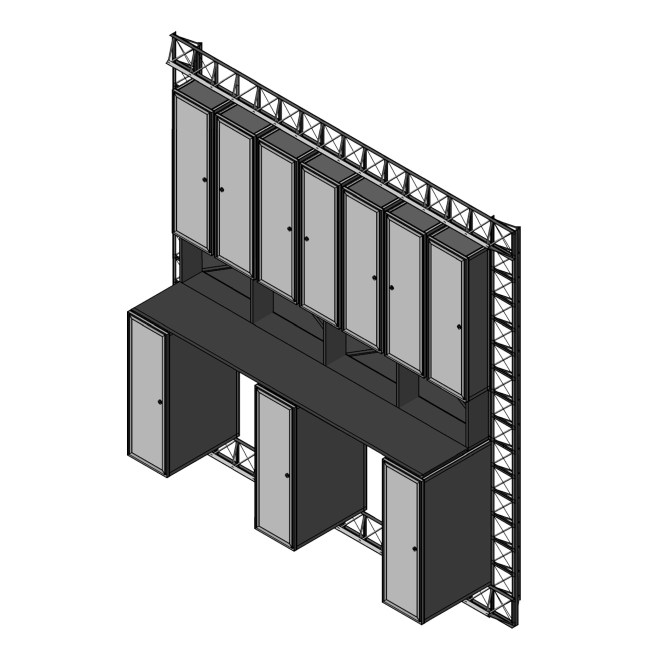

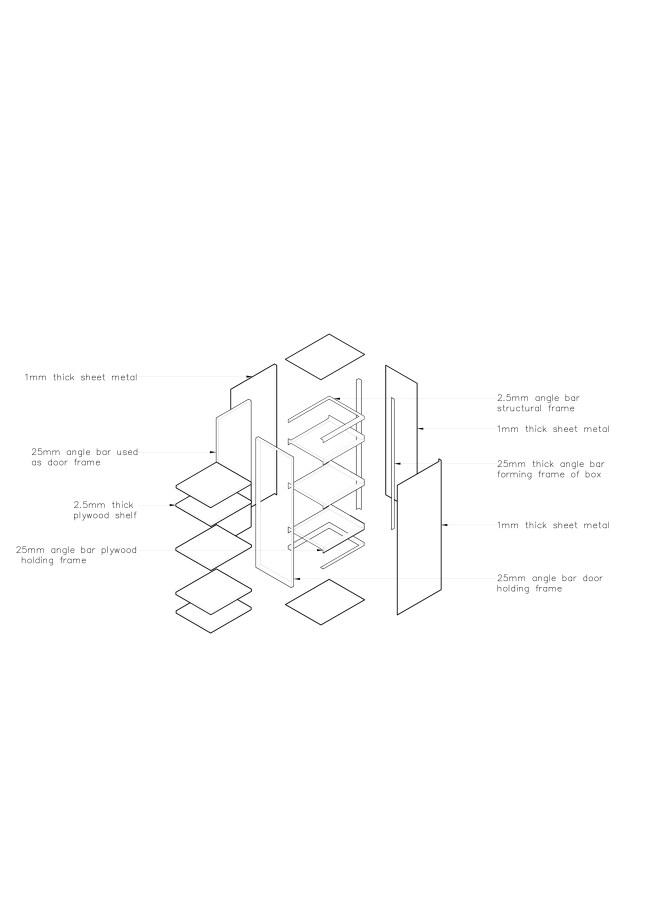

Spacecraft . locker box

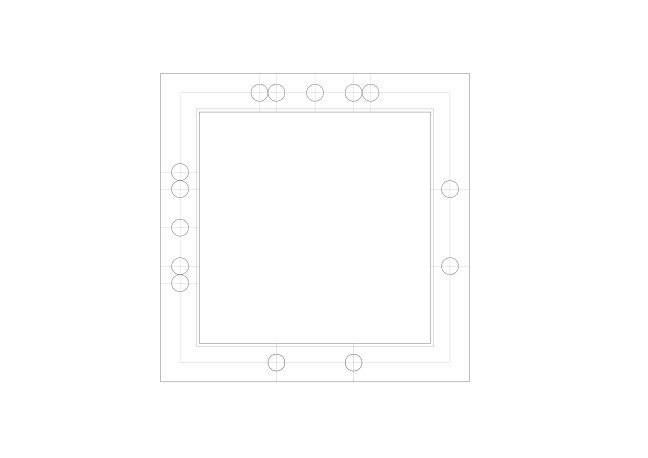

Octet truss drill template

Use a template for drilling holes in octet truss, to ensure that all holes are the same and identically located. Print on paper first,then trace or laminate onto cardboard and punch hole centers per template guides. Provided octet truss welding work is standard, dimensional tolerance of ±1 mm is achievable. Square face bolted connection is 20×20 cm, with holes of sufficient tolerance for no. 17 bolts. Drill templates are here in PDF: octet truss face joint, octet truss face joint -alt (print to A4 size sheet).

Spacecraft . octet truss fabrication process

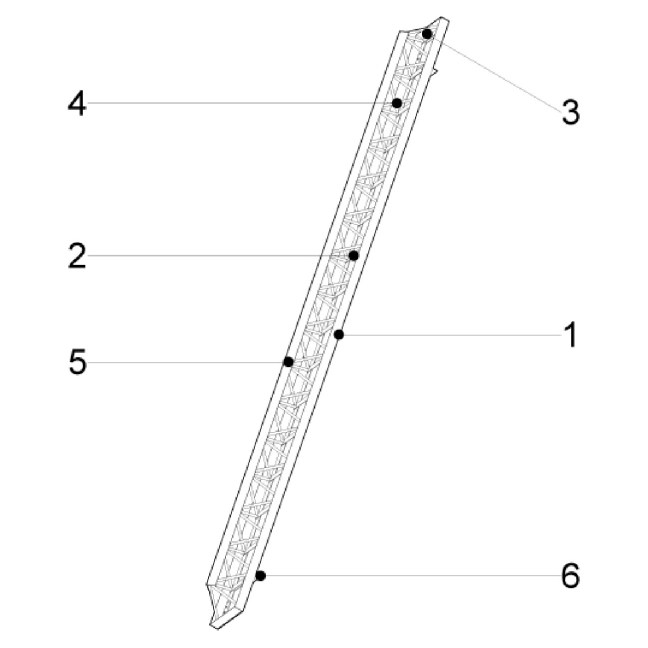

Fabrication of a semi-octet truss using 1 or 1-1/2 inch mild steel angle bar requires use of several jigs: 2d truss jig, square pyramid jig, and spacers for setting flat bar and holding string line to gauge top angle bar when welding. Each truss comprises 16 square pyramids of 4 pcs 10 or 12 mm by 16.85 cm iron rods welded to a linear array of 19.6 cm flat bar straps set in a 1 or 1-1/2 inch ms angle bar frame 20 cm wide by 282.5 cm long.

Welding: Tack weld first throughout to assemble octet truss, then complete full weld once all metal elements are held in contact. Usually a small amount of grinding required to clear sharp edges. Apply hardener coat to seal and spray 3-6 coats of automotive paint. Paint damage possible (e.g. scratches) during transport and assembly; paint touch-up work may be done after assembly.

To assembly a semi-octet truss, you will need: 2d truss jig and square pyramid jig.

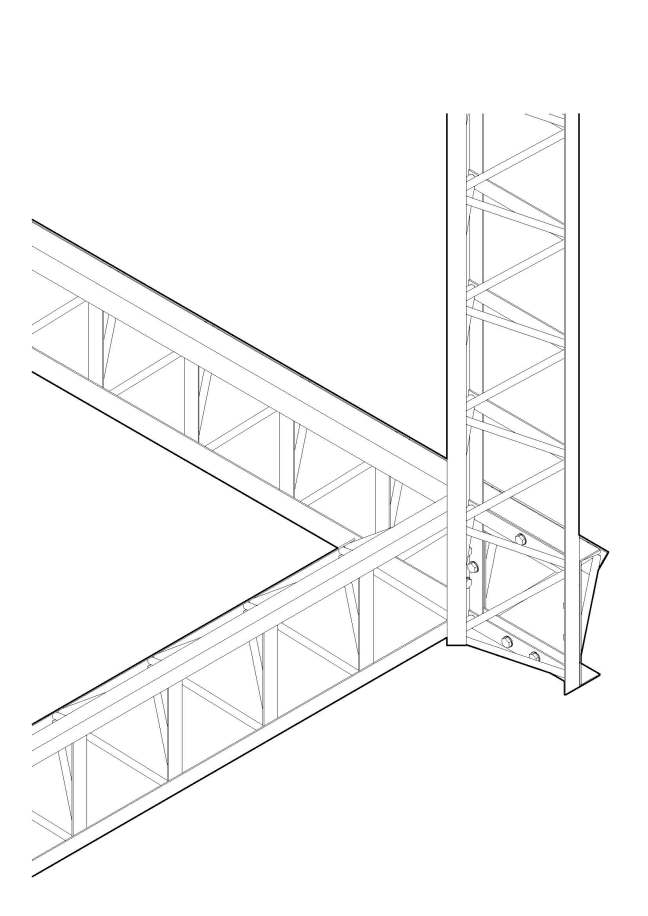

Spacecraft . octet truss face joint

The two outermost square faces of semi-octet trusses join in a bolted connection to form an octehedron. Holes for bolts should be pre-drilled for easy assembly, using this drill template or similar.

Spacecraft . octet truss 1.5in

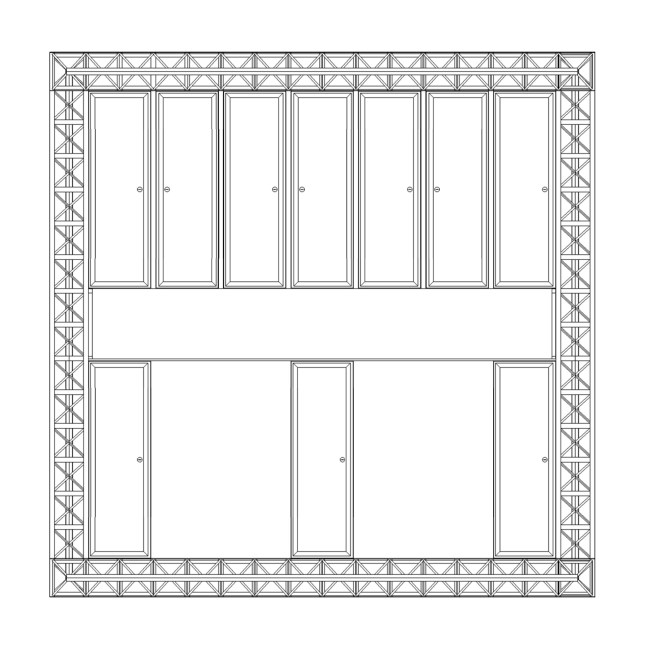

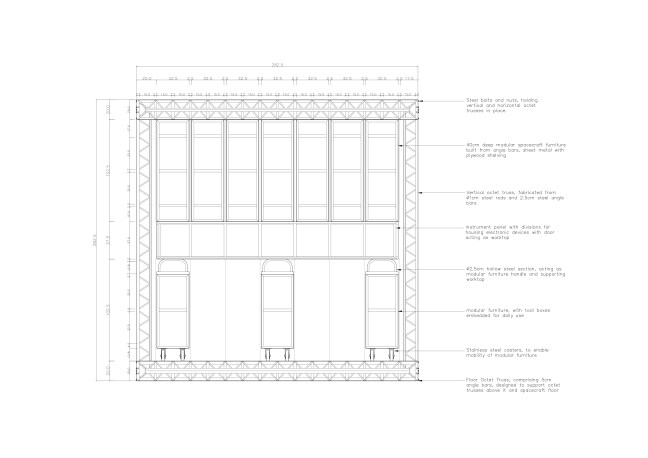

Spacecraft . floor assembly

Three (3) welded steel box trusses required for this floor assembly.

Spacecraft . infill panel walls

For more on how to make the metal storage units, see locker boxes.

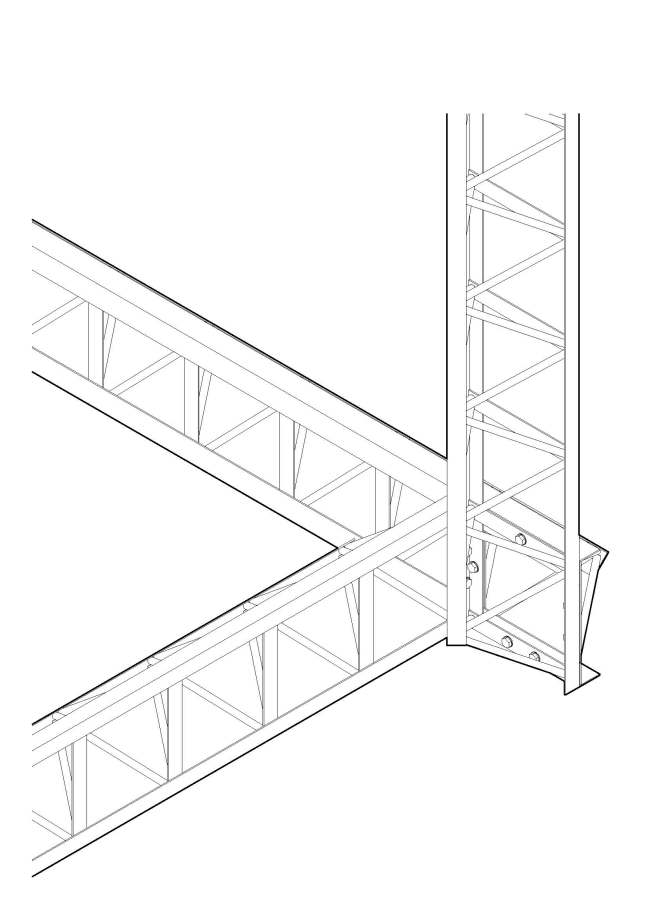

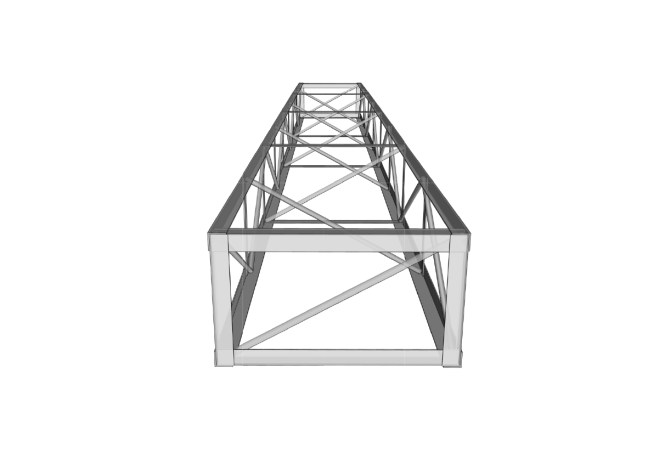

Spacecraft . box truss assembly

on flat and level ground surface, weld pair of 2d trusses together with 1-1/2in angle bar at top and bottom corners.

on flat and level ground surface, weld pair of 2d trusses together with 1-1/2in angle bar at top and bottom corners.

M&D Fall 2015

This Fall, M&D students investigated the Kiosk Tropical, the exercise was named as such after the very well known Maison Tropicale designed by Jean Prouvé. The goal of M&D courses is to let students experience peer-to-peer / horizontal learning (what happens in makerspaces or FabLabs), understand what prototyping means and learning from prototyping, learn to create open-source manuals so others can build upon their solution, explore designing and building with as little resource as possible and with and for people with no resources (i.e. be smart with the resources at hand, i.e. contribute to the circular economy). Teams had to work on a plug-in to integrate to the frame of the spacecraft. Students had also to create an Afrofuturistic image of the solution imagined.

Students experimented with the following:

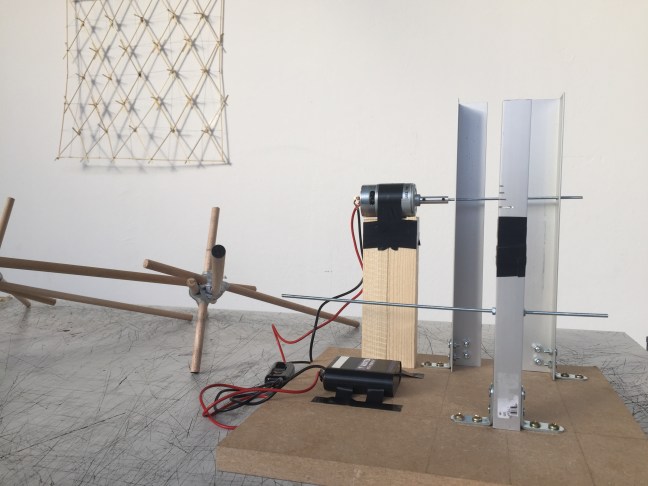

- Prototyping a machine to make PET plastic ribbons out of plastic bottles (TIBOURKI, Al Mahdi + KSIKES, Amine)

- Hacking a 3D printer to be able to 3D print using PET plastic ribbons made out of plastic bottles (ABDELKADOUS, Mouna + POUMAILLEUX, Alexis + SORTES, Thibault)

- Investigating a number of Japanese knot techniques to tie bamboo with plastic ribbons (El SOKARY, Amin + MIYAJI, Karin)

- Designing a prefabricated facade bamboo skeleton using the knots investigated and the plastic ribbons (FICINI, Elisa + JIAZHEN, Lin + KIERZKWOWSKA-KLYS, Maria + Le NAY, Erwan)

- Designing a facade system that used the facade bamboo skeleton for growing air filtering plants (CANADAS MEGIA, Pilar + GUIRARD, Vincent + LEFEBVRE, Isabelle + ORTEGA, Carla)

- Prototyping a mechanical water pump for hydroponic farming system used to water the air filtering plants (KENNEDY, Laura + STEPHENS, Amanda)

- Designing a water filtering system for growing vegetables (BONGARD, Tomas + BUREL, Clara + MORBELLI, Delna), water that also ends-up in the fish tank (part of the hydroponic and mechanical water pump system).

Thank you to OSSEO-ASARE, Dk, AMP co-founder, for being part of the mid-review. Thank you to CHICOTEAU, Félix and GIROUD, Thomas, former M&D students, for being part of the Final Jury.