First weeek =) of#ampqamp14 started at Hub Accra by a discussion of AMP’s objectives for the three coming weeeks: to co-design and build with AMP makers (comprising of STEAM students and graduates and eventually e-waste workers) a module of the spacecraft–AMP’s makerspace–and share its progress with the community in Agbogbloshie.

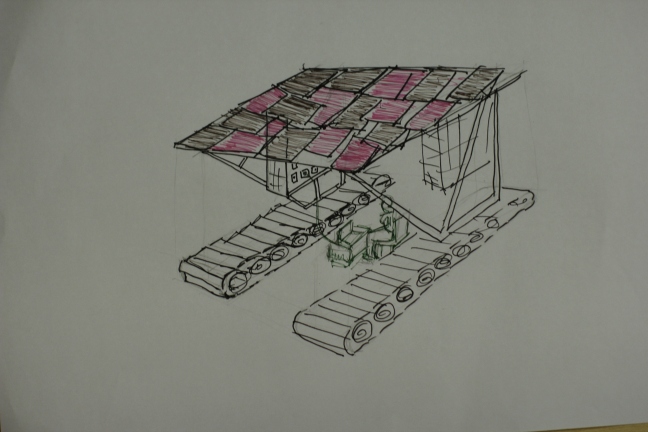

Participants started discussing the design of the spacecraft, its frame and interior frame comprising of an octet truss system, prefab panels, soft and roof systems. We then developed a critical path for each system so to know what to do at each step of the way until we build the spacecraft. The brainstorming sessions were very intensive, with some of the participants sketching/drawing the various concepts related to the spacecraft.

By the second day we enthusiastically produced fully developed critical paths, identified and quantified in terms of duration and dependency of the various tasks

We also prepared for the first workshop ahead, the plastic workshop to be carried out at the Rex Cinema in collaboration with Brad Marley and Efya from the POLY Bank GH organization. In preparation for the workshop, we conducted background research on the physical properties, melting methods and stewing methods. We sourced the plastic–shredded-PET (polyethylene therephatlate) old plastic bottles and stewed shredded-PP (polypropylene)–and a number of molds from Agbogbloshie. This was also a good occasion to share our process with the Agbogbloshie community. This is a picture of the tools we brought to the Rex Cinema to conduct our experiments.

The Rex is an open-air cinema, a wonderful space to experiment within. There, young Ghana makers were busy melting, stewing and molding different types of plastics and exploring the production of architectural parts, panels, brick or tiles, made of recycled plastic. Sam and Idrissou, Agbogbloshie community agents, helped with burning the charcoal.. They were far more skilled than us!

Below are some of the observations from the experiment:

- We observed that the PET melting process was very slow and began really late, also at temperatures slightly higher than 260◦c, which is the theoretical melting point value. PET began to char and thus underwent incomplete carbonation and changing color from a transparent blue color a marble brown colored plastic. PP however, started melting at a lower temperature and rather melted over a larger temperature range and also produced a smooth finish.

- We may have over heated the PET plastics, which led to the formation of a brittle-porous tile.

- Contributing factors to such brittleness of the plastic panel are associated to the cooling rate and media and this caused cracks.

- Also, the temperature of the charcoal flame could not be controlled and hence over heating ensued.

- It was also observed that stewing of PET did not work. This is probably due to the fact that it has a high melting temperature and the oil doing not facilitate that phenomenon.

- PP plastics however work well with stewing in oil. From the experiment, we formed a very strong mold which can be used for wall panels, table tops and many others.

Find here the Lab report.

We were honored to host Prof. Kwadjo Osseo-Asare (AMP co-PI) and Dr. Victor Oteng-Atiemo (retired from MD of DOW chemical Ghana) who gave us advices on how to proceed and continue our experiments.

Here is the link to Flickr photo set.