Presented the paper entitled: Investigated 3E Materials at Agbogbloshie in Accra, Ghana at the Raising Awareness for the Societal and Environmental Role of Engineering and (Re)Training Engineers for Participatory Design (Engineering 4 Society) conference that was held in Leuven, Belgium, June 18-19, 2015.

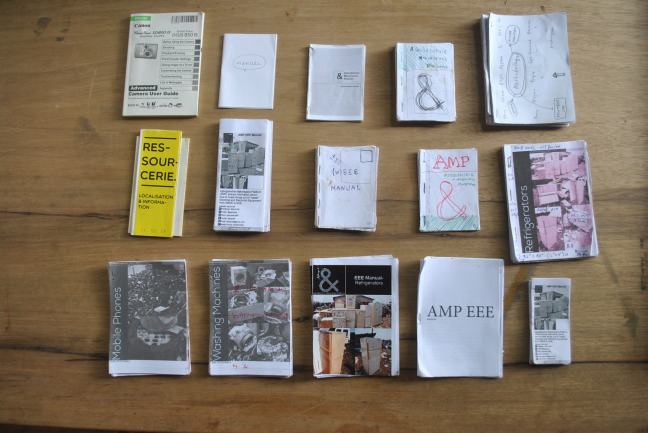

The product life cycles of electrical appliances and electronic devices impact society and the environment, given the hazardous portion present in their materials flow. Scrapping as an industry serves to decommission end-of-life (EOL) equipment, linking materials processing and recovery activities with recycling, but must be controlled against adverse environmental and human health safety factors. This work tracks an on-going effort-the Agbogbloshie Makerspace Platform (AMP)-to use participatory design methods to upgrade capabilities of the scrap, recycling and maker community located at Agbogbloshie in Accra, Ghana through co-creation of technology. The authors explain AMP’s aim to reconceptualize Waste Electrical and Electronic Equipment (WEEE or e-waste) as Electrical and Electronic Equipment (EEE or 3E): not as waste, but as inter-manipulable assemblages of 3E-materials. AMP seeks to employ a hands-on Makers and Development approach (M&D) as a collaborative process to drive interclass innovation by co-designing and fabricating a makerspace, or open community workshop and lab, and networking e-waste and scrap recyclers starting at Agbogbloshie with students and recent graduates in Science, Technology, Engineering, Arts and Mathematics or STEAM fields. The investigation at Agbogbloshie over a period of 24 months suggests opportunities for utilizing participatory design to leverage waste management and 3E-materials processing across informal sector recycling ecosystems as inputs for popular prototyping, i.e. peer-to-peer digital fabrication and distributed manufacturing.

![IMG_9888[1]](https://qamp.net/wp-content/uploads/2014/07/img_988812-e1405777262491.jpg?w=300&h=285)