Agbogbloshie e-waste dump as it is known, and portrayed by the media is more than just that. It is an e-resource repository; a source of valuable raw e-material and a makers’ paradise. On this e-turf, there are several players, whose operations make it what it is.

Zack is a young e-waste worker. He usually operates in the Agbogbloshie refrigerator trade: buying, selling, dismantling and selling again. The AMP team encountered him over 7 months ago and signed him on as a part of the AMP maker collective.

“Emeka” is a Nigerian migrant to Ghana. He owns and operates a shop out of Agbogbloshie. The shop is well stocked and has a CCTV camera which helps him secure his “goods”. Though the team had been to this side of Agbogbloshie, this was the first time we were meeting him in person.

What do all these people have in common? Computers!!

As part of the AMPQAMP at the Kokrobite Institute, AMP hackers and/or STEAM students and graduates, collaborated with hackers from the Woelab (Togo’s very active makerspace!) to build a Jerry. A Jerry is a computer that is made with parts from old computers assembled in a jerrycan. This workshop was significant, mainly due to the transfer of knowledge which occurred during the assembly process. As part of this highly didactic process, a team comprising makers from both AMP and Woelab visited Agbogbloshie.

Inside Agbogbloshie, the team first encountered a computer shop. It was well stocked and able to provide a wide range of old computer parts owned and run by Emeka. During the interviews and interaction with the e-waste workers in Agbogbloshie, the AMP team discovered that, Nigerians formed a critical part of the ecosystem in Agbogbloshie. A network that virtually spans the entire globe.

Subsequently, the team met with Zack, an e-waste worker, who is part of the AMP maker collective. Several weeks earlier, the AMP team had discovered much to our surprise that Zack whom we knew only as an expert in the commerce and dismantling of old fridges in Agbogbloshie and who had helped us with our workshop in fridge disassembly, was also a self taught computer repairer. He was comfortable enough to ask us which parts we needed, and proceeded to test them for us by connecting each in turn to his personal computer. The level of fruitful interaction had with him, points to the phenomenal possibilities that a fully operational maker collective (comprising STEAM professionals and e-waste workers) in Agbogbloshie would unleash.

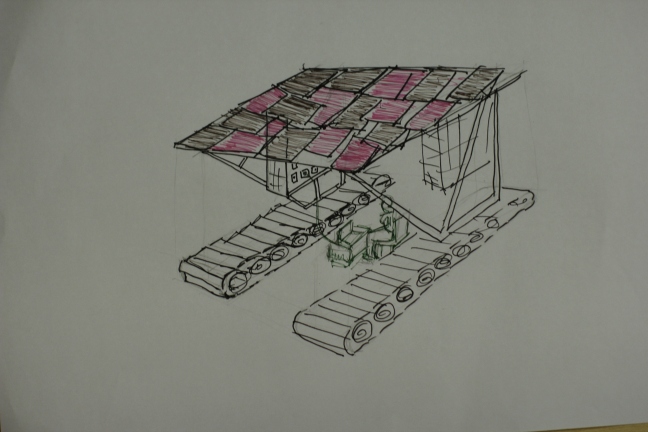

Back at the Kokrobite institute, the Woelab team, led by Rhode Audrey and Martine Pandam together with the AMP team led by Daniel started to assemble the Jerry computer. We first produced schematic sketches and then marked out and cut the JerryCan. We then placed the components: first the mother board, then the hard drives, then the cables, the power pack and finally the CD-ROM. In all, it was a very exciting experience. The excitement has spurred the AMP team on to explore further design possibilities. The team is advancing ideas such as the solar JerryTop: recovered laptop parts in a Jerrycan powered by recovered solar cells.

These we believe can serve as a means of providing cheap computers in rural areas and in deprived urban contexts and can go a long way to improve computer literacy in Ghana and Africa as a whole. This is one of those projects where hackers like Zack in Agbogbloshie and STEAM professionals like Daniel from the creativity group in KNUST (Kwame Nkrumah University of Science and Technology) could collaborate. In the few moments where language was a barrier, both teams communicated via the language of computers and making, which are both universal. Thanks to Yasmine (AMP co-pi) and Rejoice ( psychology intern and maker), such moments were minimized, as they took turns to translate.

In the end, there was a handing over ceremony where the team from Togo handed over the Jerry’s to the AMP team, signifying a transfer of technology.

![IMG_9888[1]](https://qamp.net/wp-content/uploads/2014/07/img_988812-e1405777262491.jpg?w=300&h=285)