For many designers across the globe, language (words) form the bedrock of design thinking: “Words are tools for architectural design; for the development of design intent or strategy, as well as construct the ideas that drive its creation” (Eckler, 2012) [1].

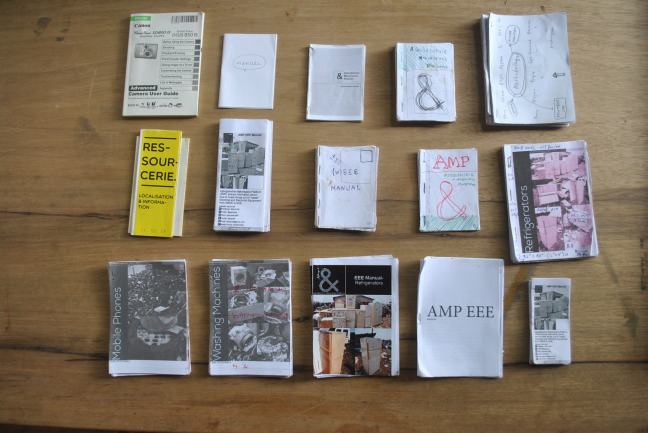

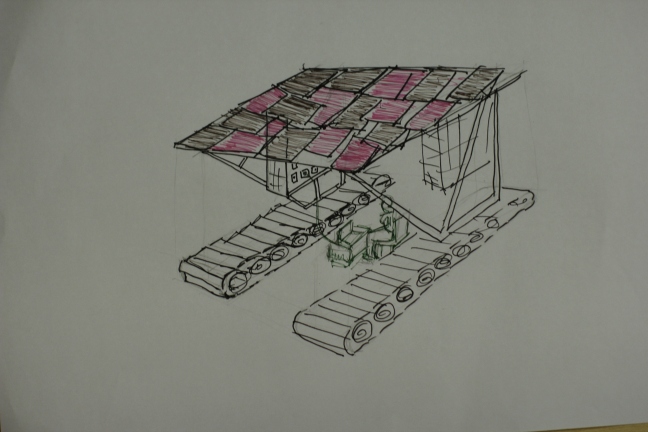

The Agbogbloshie makerspace, is essentially, a community “toolbox” for Agbogbloshie. It was conceived as a spacecraft. This choice of a word served both as a starting point and driver for the design. With AMP co-pi DK Osseo-Asare as the lead on the design team, the AMP spacecraft was designed with mobility in mind, as are other crafts like an air craft, or even space faring vehicles (spacecrafts). As a community kiosk with hand tools, the idea of crafting (making with ones hands) was pivotal in addition to the fact that, these tools enable the spacecraft to replicate itself. Hence it can be read as a place where space is crafted.

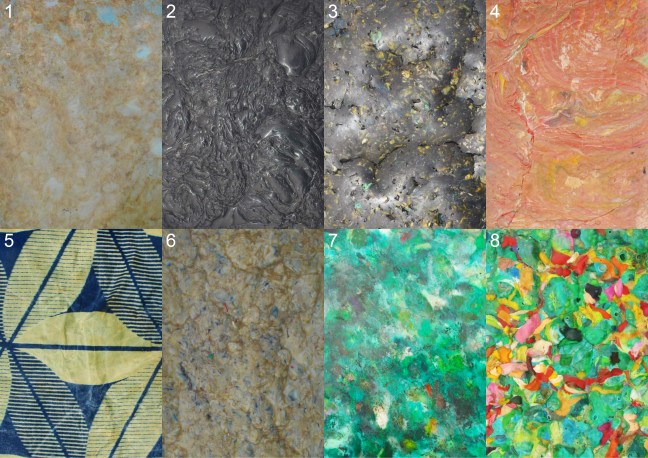

Beyond these, the influence of space travel is relevant to the Agbogbloshie makerspace. Here, the toxic electronic landscape which is unfavourable for human habitation is likened to an extra-terrestrial planetary body. Hence, the arrival of a spacecraft could imply the commencement of a process of terraforming–the hypothetical notion that, in order to be habitable and/or conducive for human habitation, atmospheres and ecology of other planets can be modified. From this point of view, the arrival of the AMP spacecraft in Agbogbloshie is the commencement of a process of spatial change or transformation, a notion which is itself deeply related to crafts (vehicles).

In summary, the spacecraft is:

- Mobile and is like other crafts

- A place for making (crafting)

- A workshop for crafting space due to its self replicating ability

- And a first step towards the spatial transformation of the Agbogbloshie landscape

In terms of the structure, the AMP spacecraft is modular and has a frame consisting of 12 octet trusses per module. (See video here). Each octet truss is made up of steel angle bars, flat plates and rods, which form a series of half octahedra all welded together into a singular structural unit. The intention is to fill in the structural frame with materials sourced from within the Agbogbloshie landscape such as old refrigerator doors, which will constitute composite “precast” insulated panels.

For the past three weeks week as part of AMPQAMP, the process of crafting the first module of the spacecraft continued starting in Hub Accra with theorizing and brainstorming about the spacecrafts systems and components, and ending in Kokrobite with the fabriacation of the first full scale octet truss, after several prototypes and mockups. It was a long tedious and yet highly exciting process where our desire for high level of precision and accuracy meant cutting and re-cutting, measuring and re-measuring, until we arrived at fairly satisfactory results.

Thanks to master welder Badu and his assistant, we had a fruitful learning experience. Their process was particularly interesting to us because, they used a grinder that was itself “e-waste” sourced from Agbogbloshie. As a space of convergence, the spacecraft which is a place for interaction and sharing (and will exist both as a tangible place, and a fully functional virtual platform) will soon land in Agbogbloshie. Stay tuned!!!

1. Eckler, F.J 2012, “Language of Space and Form: Generative Terms for Architecture”, John Wiley and Sons, New Jersey, page 1.

***

See also: